Supply and Installation

Our experienced team of surveyors and engineers can deal with any complex task. From your initial enquiry, we will ascertain if a site visit is required prior to quoting for the works. Our quotation will include best recommendations and the most suitable location for your flagpole installation. We are able to offer various methods of installation: ground mounted, wall mounted and roof mounted flagpoles. We have a dedicated supply chain that can produce bespoke fittings for a variety of installations. We can provide these in a powder coated or galvanised finish.

We hold an extensive range of flagpoles in stock enabling us to complete projects quickly and efficiently. Our qualified engineers are competent in all methods of installation including using resin anchoring systems.

Prior to commencing any works, we will produce a Risk Assessment and Method Statement (RAMS) for client approval.

Inspections and Maintenance

We are accredited by SafeContractor to carry out Inspection and Testing of Flagpoles under Provision and Use of Work Equipment Regulations 1998 ( PUWER ) To ensure your flagpole remains fit for purpose and compliant, we offer 6 monthly or annual flagpole inspections together with planned preventative maintenance (PPM) contracts.

Our engineers are qualified to work at height to carry out more complex inspections on buildings/roof mounted flagpoles. They all hold IPAF qualifications to use the appropriate access equipment if necessary.

We have a comprehensive range of spare parts for all of your maintenance needs and for all different types of flagpoles, irrespective of age.

Our safety inspections and maintenance for fibreglass and aluminium Flagpoles include:

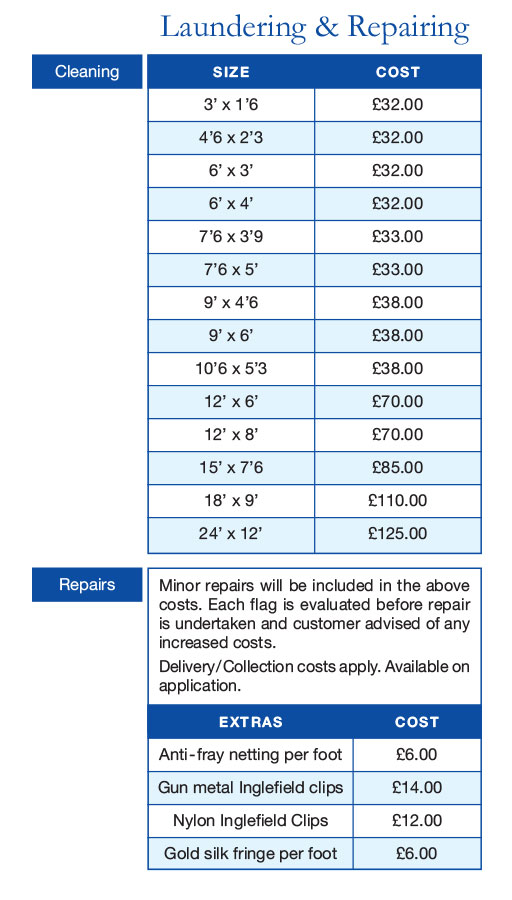

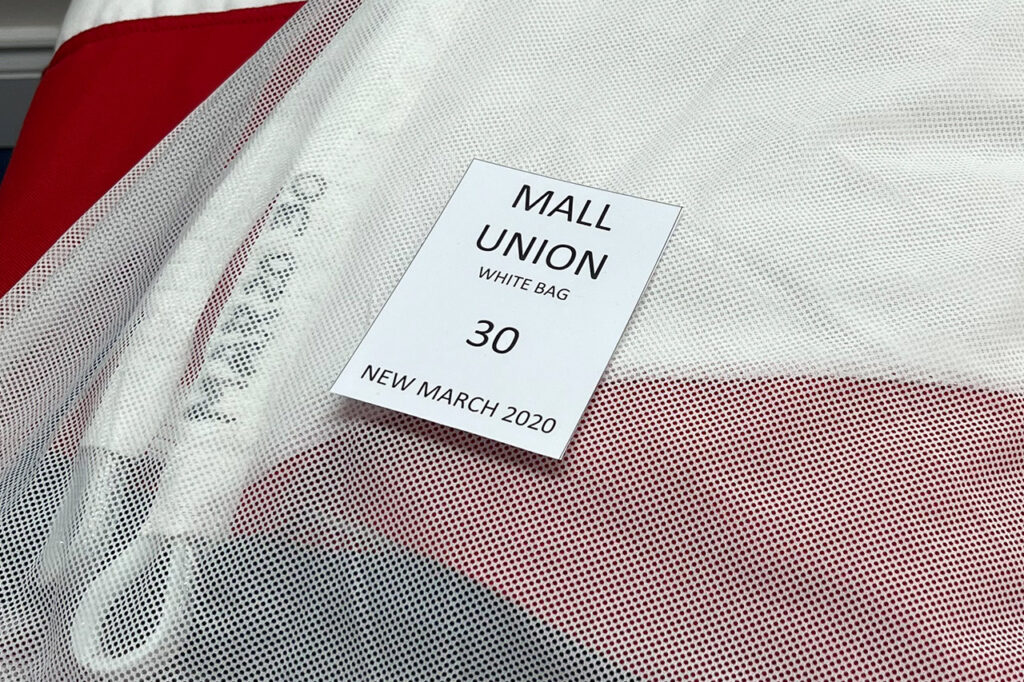

Flag changing services and Laundering

We provide flag flying services either on a contract or ad hoc basis. Your flags represent your values and it is important to maintain them so they always look their best. We offer specialist flag cleaning services for all flag sizes inclusive of minor repairs to help prolong the life of your flags. We can arrange to attend your premises and remove the flags.

Our services include:

Flag washing and rotation

Flag repair where practical

Replacement flags

Half masting flags

There are also official flag flying days on UK Government buildings for the Union flag, and other flag flying events that are now observed